Iron foundry basics

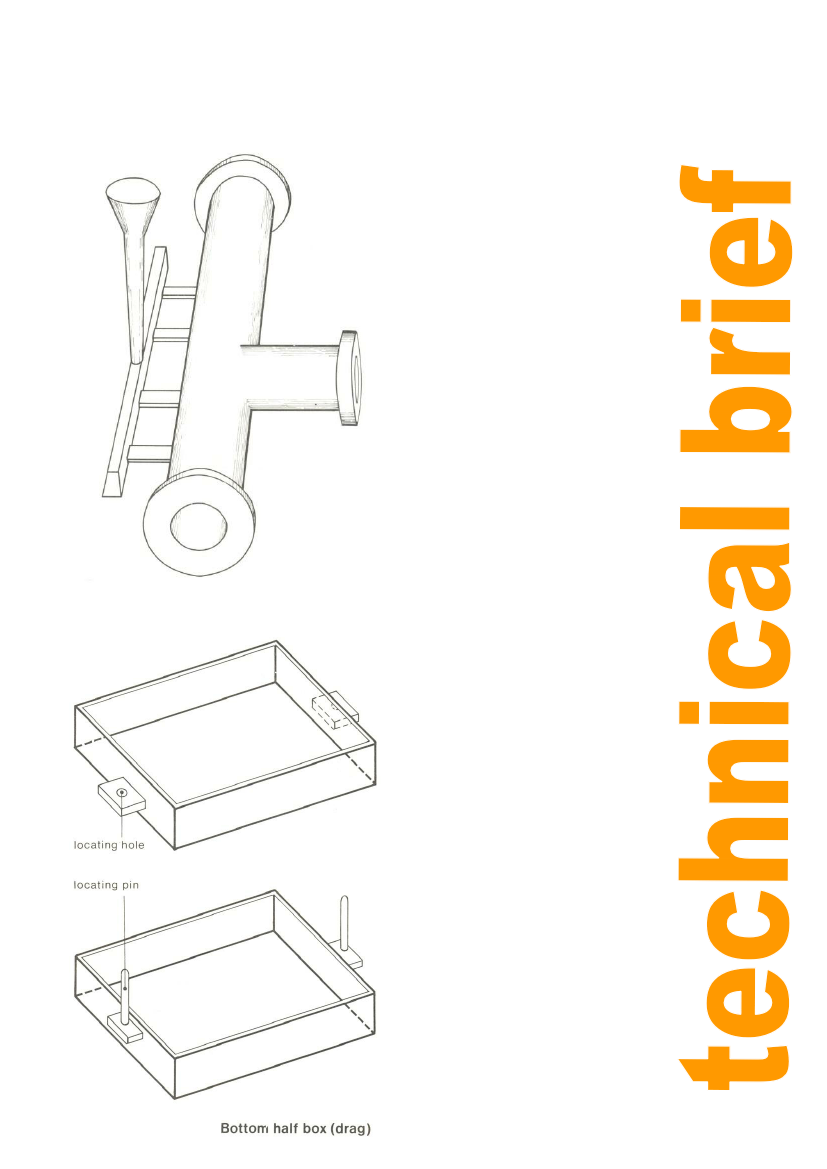

Figure 9: Casting and runner system

10

Practical Action

Moulding

Moulding, in simplest terms, consists of

burying or pressing a pattern into

specially prepared sand, which will

retain the shape or imprint of the

pattern when the latter is removed. Into

the impression that is left, molten metal

is poured and allowed to cool, after

which it is removed in a solid state. The

making of the mould, however, is not

quite as simple as it would appear from

this description. Sometimes, in fact,

castings are required with hollow

portions and this is done by inserting

cores, which adds to the intricacy of the

mould. Other problems can arise, which

make moulding a highly skilled and

exact art. For example, gases are

generated, both in the mould and the

cores, when molten metal comes into

contact with the damp or green sand, as

it is known in the foundry. For certain

castings where sand is not sufficiently

permeable, these gases have to be led

away through fine vents so that they do

not find their way into the metal and

cause bubbles or blow holes. Again, the

rush of molten metal may cause the two

halves of the mould to separate, or the

cores to float, with the result that

castings are obtained which are thicker

than they should be, or not true to

pattern. To avoid these problems, the

art of moulding will be explained in

more detail, but will only cover small

moulds, that is those which are easily

handled by one man and made in a

moulding box.

Figure 10: Top half box (cope)

A moulding box consists of two

rectangular frames of equal size, each

of which is open at the top and bottom.

The bottom box, or drag, has a fixed

locating pin at each end, which fits into

two holes in the top box or cope. Boxes

are usually of metal construction and

vary in size.to suit the size of pattern to

be used (Figs. 10, 11 and 12).

When choosing a moulding box, care

must be taken to allow sufficient room

around the pattern to obtain a good

solid mass of sand, between the edges

of the pattern and the sides of the box

and also in depth. A flat board is

required on which to place the moulding

box. The half pattern (without the dowel

pins) is placed on the board and the

bottom half of the moulding box (the